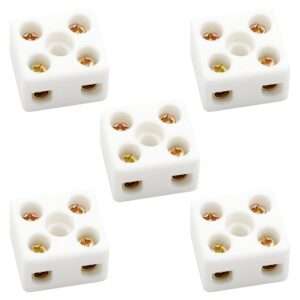

Porcelain terminal blocks are electrical connectors made from porcelain, a ceramic material. These terminal blocks are designed to provide a secure and insulated means of connecting and terminating electrical wires or conductors. Porcelain, known for its excellent insulating properties and durability, makes these terminal blocks suitable for a variety of electrical applications.

Key features of porcelain terminal blocks may include:

- Insulation: Porcelain provides high electrical insulation, preventing the flow of electrical current between terminals and minimizing the risk of short circuits.

- Heat Resistance: Porcelain has good heat resistance, making these terminal blocks suitable for applications where there may be elevated temperatures.

- Mechanical Strength: Porcelain is a strong and rigid material, offering mechanical stability to the terminal blocks.

- Chemical Resistance: Porcelain is resistant to many chemicals, enhancing the durability of the terminal blocks in different environments.

Porcelain terminal blocks are commonly used in various industrial and electrical applications where reliable electrical connections and robust insulation are essential. They may be employed in control panels, distribution boards, and other electrical systems. The use of porcelain ensures that these terminal blocks can withstand harsh conditions and provide long-lasting performance.

SPECIFICATION –

Inserts: Nickle Plated Brass

Housing: Porcelain (Glazed Option)

Temp: 800ºC (Housing),

Screw: Galvanised Steel

Standard: CE ( BS EN 60998)

Color: White

FEATURE –

Hard & Solid

Very High Temperature

Non-Inflammable

Resistant to chemicals

Do you have a question?

Drop us a line by compiling the form below. We will be more than happy to reply to any of your questions!